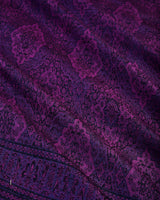

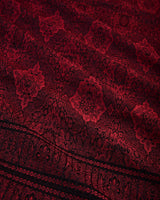

Face-off. Handloom vs Powerloom Sarees. Understand the differences to make an informed buying decision.

Is you saree an authentic handloom saree? And even if it is, is it worth the premium you paid for it over similar-looking powerloom products. Lets explore.

In any Indian textile construction, there are 3 principal yarn components-

- the primary warp,

- the primary weft, and

- the supplementary warp or supplementary weft.

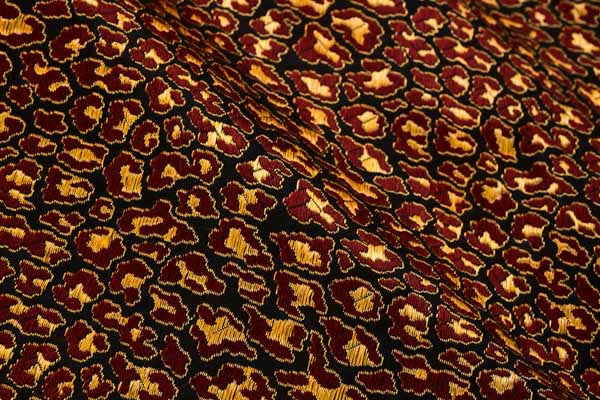

Warp is the thread that runs along the length of the fabric, and weft along the width. In a brocade weave, the primary warp and weft weave the base fabric and the supplementary warp or weft are used to weave the motifs. A satin Tanchoi weave, in contrast, uses a higher warp count instead of a supplementary warp or weft, to weave the motifs. So, while in a brocade, the motifs appear to be embroidered onto a base fabric, in a Tanchoi, the motifs are integrated in the base fabric itself.

In most textiles, whether handloom or powerloom, the warp is fixed, ie it is installed on the loom before the weaving starts. Once installed, the weaving can start by throwing the weft yarn, that passes through a shed or openings between the pre-installed warp. The shed is created by raising select warp yarns at designed intervals with the help of a jacquard installed on top of the loom. It is this throwing of the weft that marks the key difference between a handloom and a powerloom.

In a handloom, the weft yarn, rolled inside a shuttle, is thrown by hand. This throwing is also referred to as the pick motion. In a powerloom, the pick motion is achieved by using specialised machines.

A: The Cost

Because powerloom production is faster and requires lesser manual processes, it is relatively less-expensive compared to a handloom textile.

In the context of banarasi textiles, a powerloom can produce anywhere between 5-25 meters of fabric a day. In contrast, handloom manufacture usually ranges between 10-80 centimetres, that is less than a meter a day, depending on the design.

While the cost-saving using a power loom is welcome, the speed presents some important corollaries:

- The speed of a powerloom may negate the possibility of using the delicate pure silk yarns. Pure silk yarns are delicate and may break during high-speed weaving affecting the quality of the textile being woven.

- While saving on the labour cost, using pure silk on a powerloom significantly increases the yarn cost as much larger quantities will be used and produced. One unsuccessful design can block significant working capital for the manufacturer.

- Because of larger quantities being made and marketed, a powerloom product tends to be less exclusive compared to a handloom textile that has very limited production.

- Because the products are sold at lower prices and target mass market, often the manufacturers do not pay enough importance to the design and finesse.

Because of the above factors, powerloom production almost always use blended yarns. Similarly, handloom textiles almost always are made with pure yarns.

B: The Design

Because of the hand-picking, there are certain designs that are only possible on a handloom. For instance, in a Kadhuan weave, the motifs are woven by moving the weft only in the motifs areas. This makes the motifs more attractive, and also negates the need for cutting the hanging loose motif yarns at the back, which is otherwise necessary if they were thrown across the full-width instead of just the motif areas. This selective movement of motif yarns is not possible on a powerloom. So they can not be used to weave a Kadhuan design.

Similar to Kadhuan, techniques like Kadiyal, that uses different primary wefts in the body and the border to achieve sharp contrast, or Rangkaat, where more than one primary weft is used to achieve a multi-color base fabric, are only possible on a handloom.

C: The Verdict

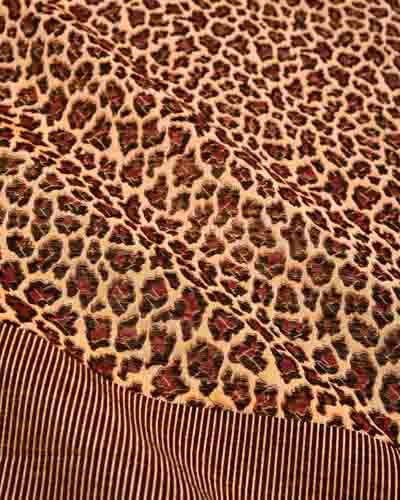

While handloom holds a very special place in our hearts, we do not look at powerlooms with disdain. For many users, a value-for money analysis can tilt the balance in favour of powerlooms as they do offer the possibility of making beautiful textiles at low costs. At HolyWeaves, we use them to make some beautiful sarees and offer them at very attractive prices in our Budget Brocade Collection. These sarees are great for normal occasions, gifting, and even regular wear. Because they use blended yarns, they often also require less care compared to a pure silk handloom saree.

A handloom product, on the other hand, is the way to go if you are looking to buy something exclusive, for yourself or your loved ones. Every handloom saree is an heirloom product that can be passed onto generations. Also, when you buy a handloom product, you directly contribute towards providing employment to a weaver for 15-30 days.

While powerlooms have replaced handlooms the world over, they live on in India. They sustain not because manufacturers like us are still practising this age-old craft, but because there are connoisseurs like you who value the heritage, and are willing to pay the price for the craft. And you deserve our sincere gratitude.

Related Collections:

If you liked our post, and would like to see more such original content, please do leave a comment before leaving.

4 comments

I want to know about the manufacturing cost of a saree and how many quantity of looms about use for make a one saree

Praneeth Akalanka

How to distinguish between power loom and handloom products?

This is how I do?

I closely examine weft threads arrangement. If they are regular, even, and look like being placed by computer, that is known as power loom.

If weft threads are irregular and uneven, that fabric is handloom.

Dr. Appalayya

According to your clarification between hand loom and power loom is correct now a days very problem in both hand loom and power loom because the main reason is short of labour and less demand due to ladies are moderate by useing chudidar and leggings only modern ladies attracted by dresses no new commer in this weaving field so many weavers in cities gone to security guards even centeral and state gout not supporting this industry

H C Jayaswamy

Excellent article ! Great information

I have a question though, how can we know if the saree is Handloomed or power loomed by looking the back side of a brocade georgette saree ?

Lakshmi uma bharathi Rachakonda

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.