Face-off. Handloom vs Powerloom Sarees. Understand the differences to make an informed buying decision

When choosing a saree, authenticity and value are essential considerations. Is your saree genuinely handloom? And even if it is, does it justify the premium over similar-looking powerloom products? Let’s explore.

Understanding Textile Construction

In Indian textiles, there are three principal yarn components:

-

Primary warp: Threads running along the fabric’s length.

-

Primary weft: Threads running across the fabric’s width.

-

Supplementary warp or weft: Threads used to create motifs or patterns.

In brocade weaving, the primary warp and weft form the base fabric, while the supplementary threads create motifs that appear embroidered onto the base. A satin Tanchoi weave, in contrast, uses a denser warp count rather than supplementary threads, integrating motifs seamlessly into the fabric.

In both handloom and powerloom textiles, the warp is pre-installed on the loom before weaving begins. The weft thread is then passed through the shed—the space between selected warp threads—which is raised using a jacquard mechanism. The key difference between handloom and powerloom lies in how the weft is inserted:

-

Handloom: The weft is manually thrown using a shuttle, a process called the "pick motion."

-

Powerloom: The pick motion is mechanized, enabling faster weaving.

While most handlooms, though varying in size and orientation, adhere to the traditional method of manually throwing the shuttle carrying the weft and inserting it amidst the openings in pre-installed warp, powerlooms have evolved into diverse types with advanced weaving techniques. Some powerlooms, like pick-and-pick looms, replicate handloom methods and have recently ventured into weaving pure silk yarns. Modern rapier looms stand out for their remarkable speed and shuttle-less operation. Designed primarily for man-made fibers, these looms prioritize efficiency and high-volume production.

The Cost Factor

Powerloom production is significantly faster and involves fewer manual processes, making it more economical overall. In the context of Banarasi sarees, a powerloom can produce 5–25 meters of fabric daily, compared to a significant lesser 10–80 centimeters produced on a handloom, depending on the design's complexity.

Although pure silk yarns have now started to be used on powerlooms, they are prone to breakage under high-speed weaving. While labor costs are reduced, the use of pure silk on powerlooms substantially increases yarn expenses due to the larger quantities consumed during production. Moreover, defects caused by yarn breakages and mechanical issues can lead to considerable losses. One unsuccessful design can tie up significant working capital, which is why pure silk sarees are rarely produced on powerlooms, despite recent technical advancements.

On the other hand, weaving poly silk sarees on a handloom is not prudent, as the end product fails to justify the higher weaving costs.

Exclusivity and Design Versatility

Handloom sarees, crafted meticulously over 10 to 60 days, embody true exclusivity. Produced in much smaller quantities, their colors often vary with each piece, and designs are rotated after only a few iterations. This ensures a unique charm, making it rare to find two identical handloom sarees. In contrast, a successful powerloom design can be mass-produced in thousands, increasing the likelihood of encountering someone wearing the same saree at a gathering.

Moreover, certain intricate designs are only achievable on handlooms due to the manual weaving techniques they employ. For example:

-

Kadhuan Weave: Motifs are diligently woven by moving the weft selectively within motif areas. This eliminates floating threads requiring to be cut at the back, and enhances motif definition, which is impossible on powerlooms.

-

Kadiyal Weave: Different color primary wefts are used in the body and border connected using dovetail joints to achieve sharp contrasts .

-

Rangkaat Weave: Multiple primary wefts create a multi-colored body with intricate dovetailing, and overlaid with zari brocading.

However, powerlooms offer distinct advantages in design. Thanks to computer jacquards, experimenting with designs has become far simpler and more efficient on powerlooms than on handlooms. Creating larger motifs, like an expansive paisley that spans the entire width of the saree, is much easier and cost effective on a powerloom paired to a computer jacquard. Producing such large motifs on handlooms is difficult and costly, requiring substantial investment in manual graphs, jacquard cards, and significant labor during weaving.

Additionally, powerlooms make it easier to quickly create multiple design and color samples, test variations, discard those that don't work, and refine the final result. In contrast, on a handloom, any design requires upfront investment in graphs and jacquard cards, meaning that if the final result doesn’t meet expectations, the upfront cost is wasted. This is one of the key reasons powerloom sarees often showcase a broader range of designs, while handlooms tend to focus more on traditional designs. However, this flexibility of powerlooms presents a significant challenge: the rapid replication of beautiful handloom sarees, albeit using artificial yarns and devoid of the exclusive techniques that define handwoven textiles. This poses a significant challenge for handloom businesses like ours, who invest substantial time and resources in developing these exclusive designs.

The Verdict

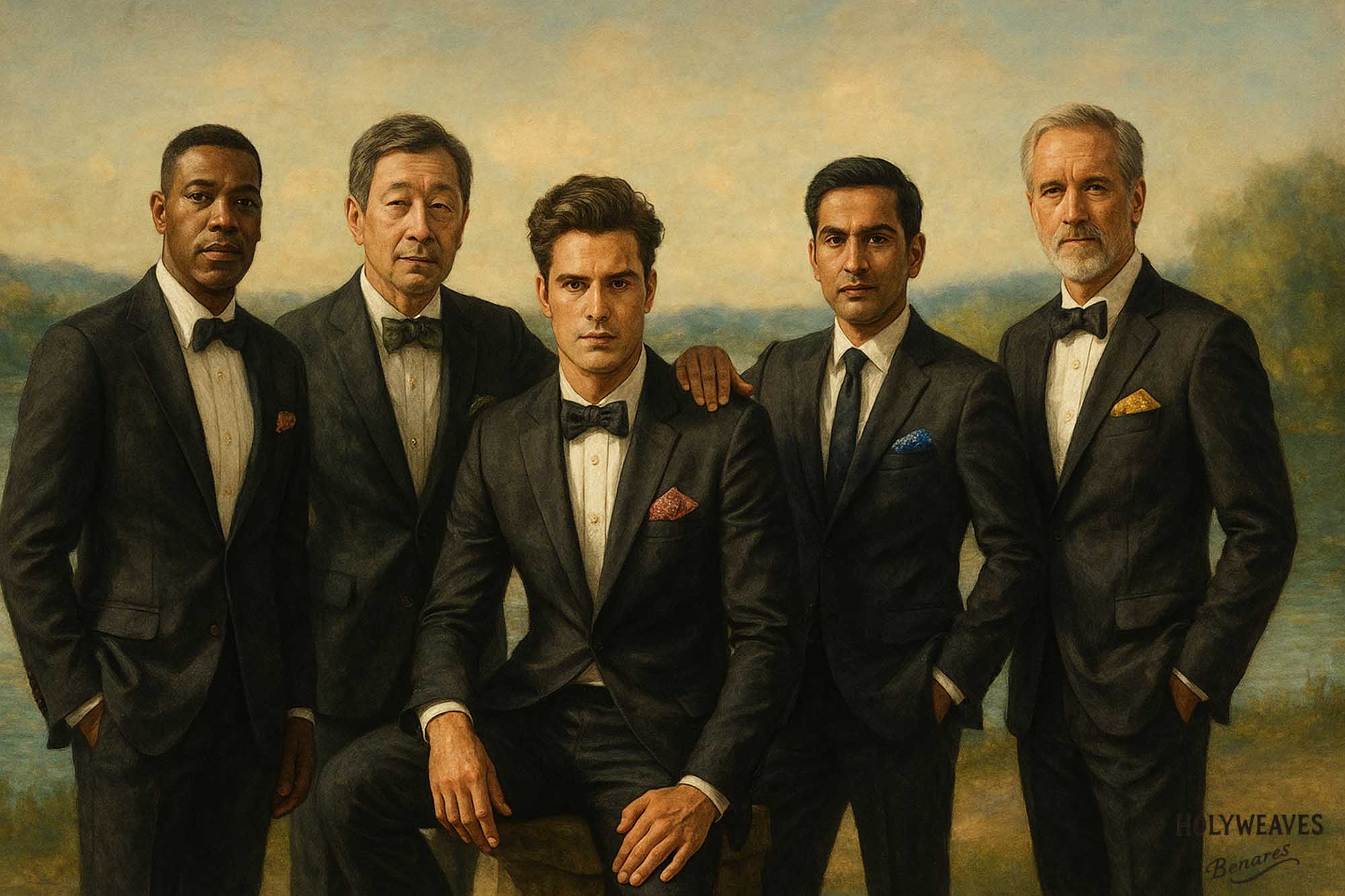

While handloom holds a very special place in our hearts, we at HolyWeaves do not look at powerlooms with disdain. They provide valuable opportunities for extensive design experimentation, rather than simply being used to replicate handwoven masterpieces- something we don't encourage. For many users, powerloom sarees can be an excellent choice for affordability and practicality.

However, if you seek something exclusive and heirloom-worthy, a handloom saree is unparalleled. Beyond its aesthetic and cultural value, each handloom saree represents 15–60 days of an artisan's meticulous workmanship. Your purchase also directly supports traditional crafts and sustains livelihoods. India’s handlooms endure not just because some artisans continue practicing this age-old craft, but because connoisseurs like you value their heritage and are willing to invest in them.

An important word of caution to conclude. While we hold both handlooms and powerlooms in high regard for their unique strengths, we strongly disapprove of powerloom sarees made with poly silk yarns being misrepresented as handloom or pure silk. We urge buyers to exercise discretion and remain cautious of such deceptive practices. It’s essential for buyers to have realistic expectations regarding quality in relation to price. Those who demand unreasonable pricing and purity often find sellers willing to cater to these expectations, albeit at the expense of ethical standards.

Try our exquisite Handwoven Sarees to experience the unmatched craftsmanship and timeless elegance they offer. Also Explore our Nityam Collection for the beauty of handwoven aesthetics at an affordable price, crafted using innovative powerloom techniques. These can be ideal for gifting, regular wear, or casual occasions.

If you liked our post, and would like to see more such original content, please do leave a comment before leaving.

4 comments

I want to know about the manufacturing cost of a saree and how many quantity of looms about use for make a one saree

Praneeth Akalanka

How to distinguish between power loom and handloom products?

This is how I do?

I closely examine weft threads arrangement. If they are regular, even, and look like being placed by computer, that is known as power loom.

If weft threads are irregular and uneven, that fabric is handloom.

Dr. Appalayya

According to your clarification between hand loom and power loom is correct now a days very problem in both hand loom and power loom because the main reason is short of labour and less demand due to ladies are moderate by useing chudidar and leggings only modern ladies attracted by dresses no new commer in this weaving field so many weavers in cities gone to security guards even centeral and state gout not supporting this industry

H C Jayaswamy

Excellent article ! Great information

I have a question though, how can we know if the saree is Handloomed or power loomed by looking the back side of a brocade georgette saree ?

Lakshmi uma bharathi Rachakonda

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.